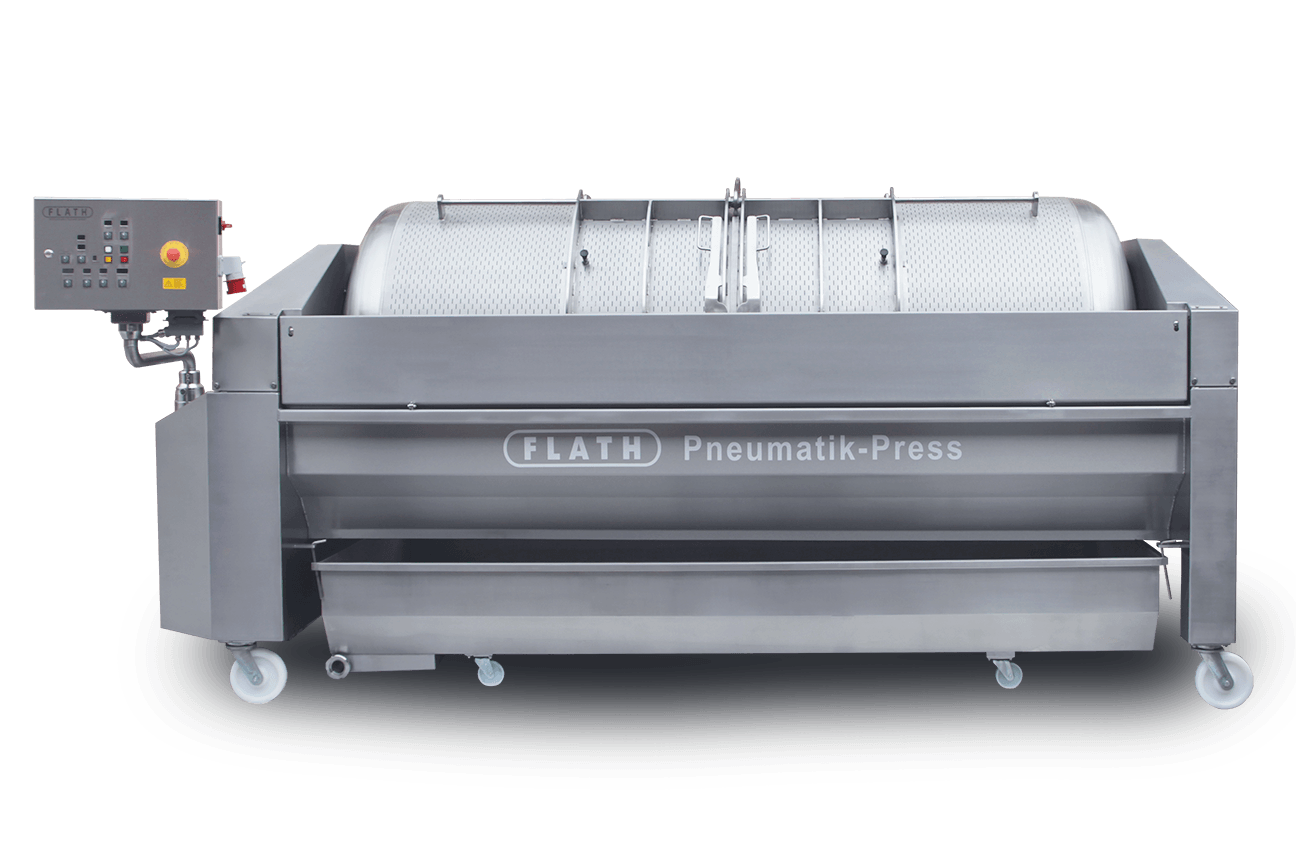

Flath Pneumatic-Press

Flath Pneumatic-Press

Wine presses between 2.000 to 12.000 litres capacity.

Half-open, closed or as intermediate version.

half-open

The classic pneumatic press with caracterisitc short pressing times, easy to clean and nearly complete self emtying.

closed

Equiped with a hermetically closing door the closed version is the choice for reductive pressing.

dual

The combination of many advantages. Coverable slits enable mesh fermenting inside the press and short drainage times.

Advantages at a glance

application and service centered

Speisekarte

Speisekarte

Control of the press via intuitive touch display

Programs optimized for your harvest delivered by us or almost infinite space for your individual programming. Both are possible with IMPULSE. All information about press status and program flows at one glance.

The swivel arm

important core element

The control mounted on the swivel arm can be removed easily, so it's possible to store it in a warm and dry place while it's not being used. This significantly reduces damage to the electronics. The flexible positioning of the arm allows operation at eye level even with elevated presses.

Press systems

Options

- Gangway

- Cleaning system

- Pneumatic lid opening

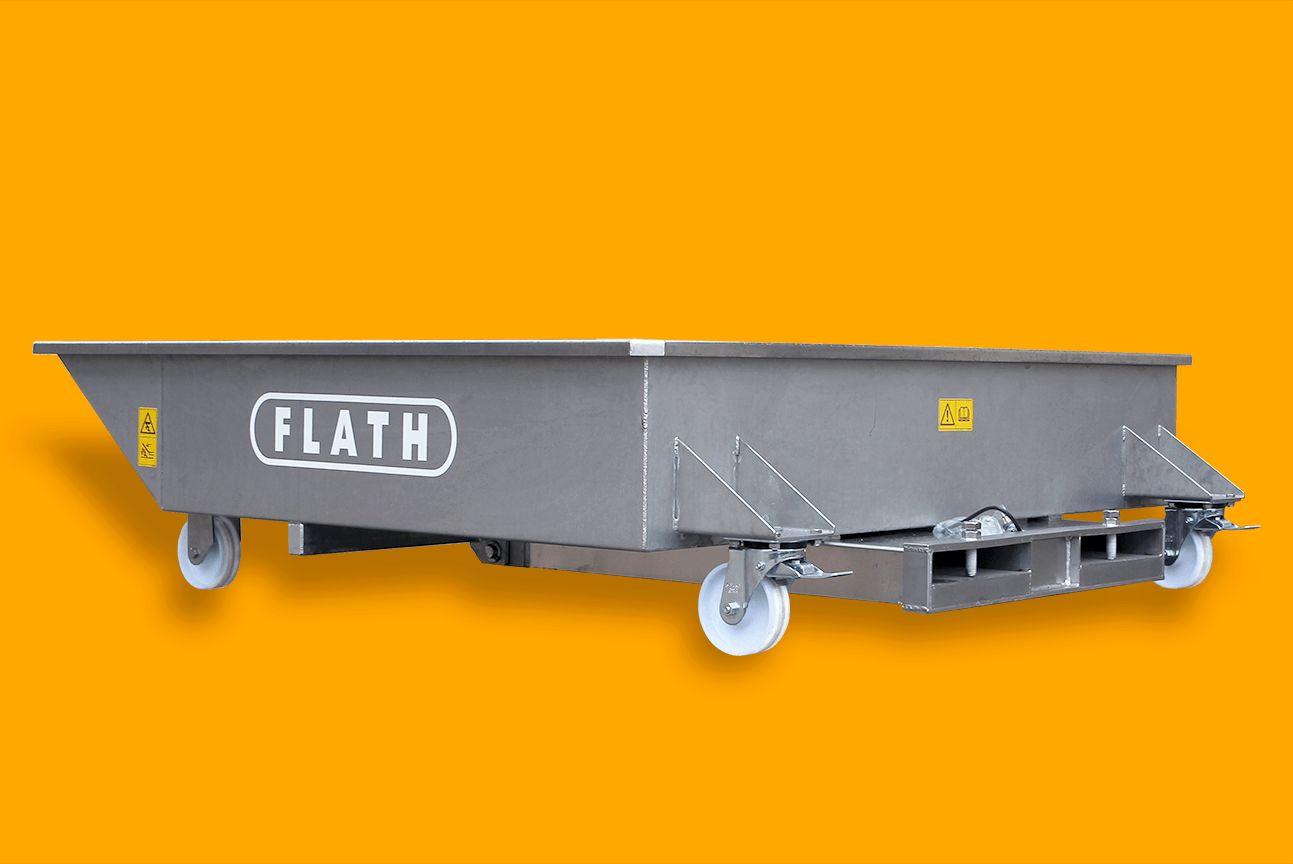

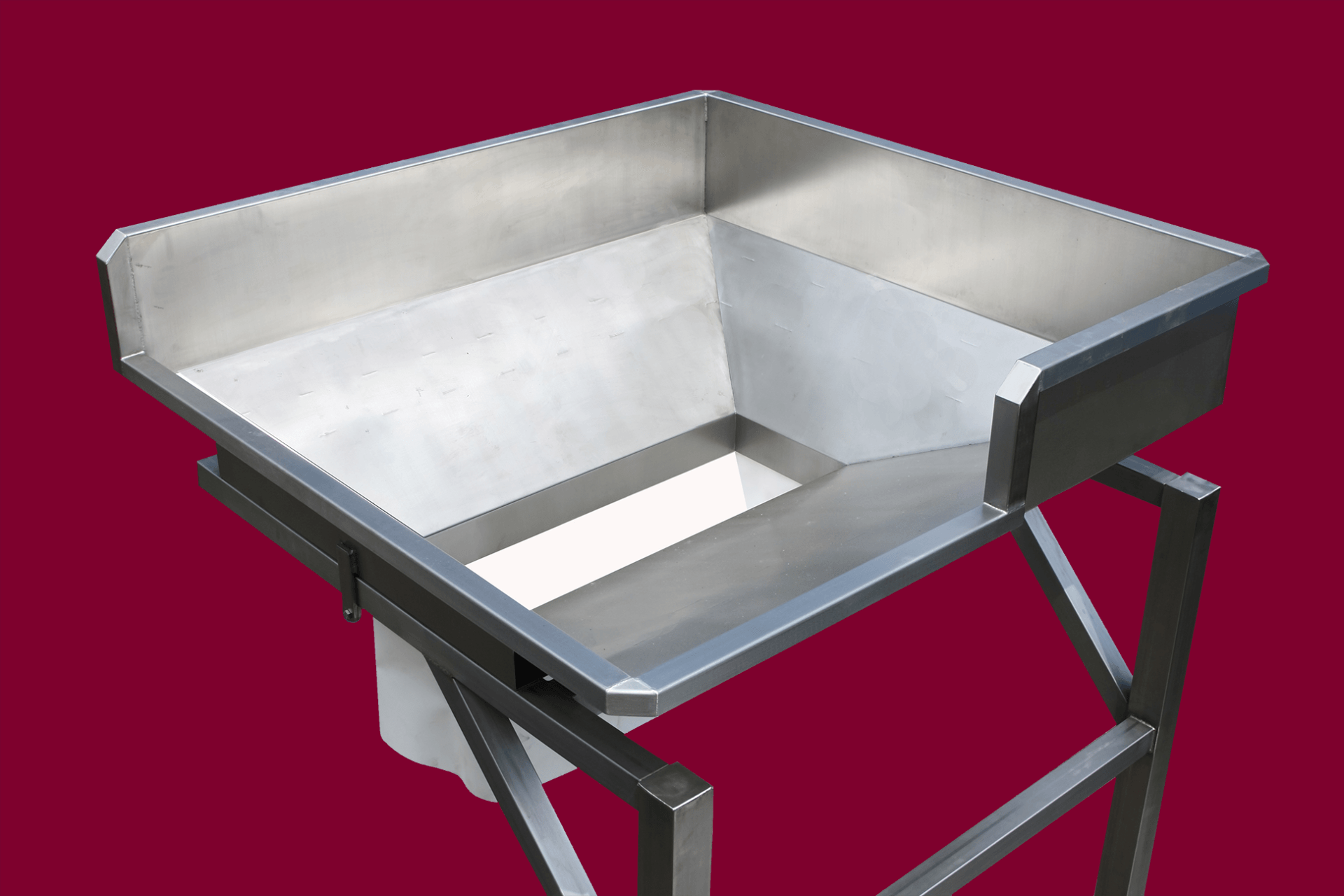

- Various juice basin versions

- Remote control with various functions

- Dimensionally accurate increasing of the rack

- Offset filling openings

- Cooling jacket

- Pressure warning device for central filling

- Level control

- Overflow protection

- Various rotation speeds of the press drum

- electrical traction drive

- and much more